SUSTAINABILITY

Environmental Green Footprint

We believe in the importance of environmentally friendly printing processes. We operate using guidelines from the Sustainable Green Printing (SGP), the leading non-profit accreditation organization that promotes sustainability in printing practices and manufacturing operations. We are committed to continuing these sustainability standards within our operation and continually improving our processes so that they have minimal impact on our environmental.

Newsprint

White Birch, our newsprint supplier, uses 100% Thermo Mechanical Pulp (TMP) in production of all our newsprint. TMP uses wood chips from sawmill floors, that used to be land filled, resulting in less trees being cut down. White Birch is part of the Forest Stewardship Council. Trees cut down must be replaced with new trees, trees are cut for lumber not newsprint.

Ink

Our ink is purchased from Flint Group. The press uses Coldset Inks that are oil based. They are made with renewable resources. Renewable resources make up between 4% to 17.8% of the content of the inks. Flint Group has long since incorporated soy oil into our web offset coldset inks. Flint Group is a Patron and one of the original stakeholders in Sustainable Green Printer Partnership.

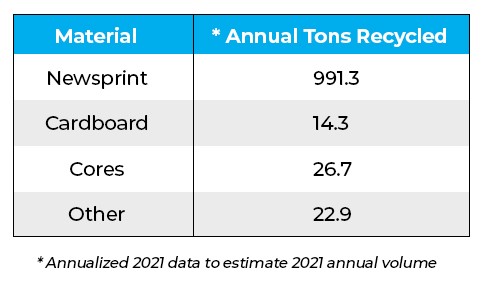

Recycling

We do not throw away any paper or cardboard. All unused newsprint, test pages, cardboard, cores and other paper based materials are recycled. We use Gordon Recycling to recycle paper based materials.

Plate recycling

We use United Metal Traders to recycle our metal printing plates. We recycle roughly 30 tons of metal per year.

Energy efficiency

Susquehanna Printing’s use of coldset printing means that our press is more energy efficient than a heatset printing press because we do not need to use extra energy to run dryers. We are focused on resource management of water through careful controls of water usage throughout the facility.